Assan Panel, which aims to increase its product range in roof and facade cladding, which is described as the shell of the building, offers solutions for all roof and facade systems in line with customer demands by adding Polycarbonate sheet materials compatible with sandwich panels to its product range.

Assan Panel continues its values, which it attaches importance to in sandwich panel production; raw material quality, effective assembly service with its authorized dealer network, quality production in accordance with TSE EN and ISO norms and quality control at every stage from raw material input to delivery, with the same meticulousness in Polycarbonate sheet production. With this understanding, it has become one of the leading organizations leading the sector.

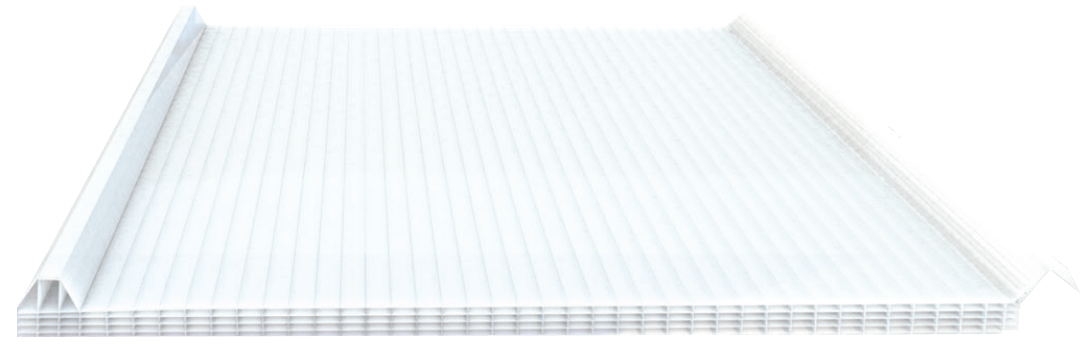

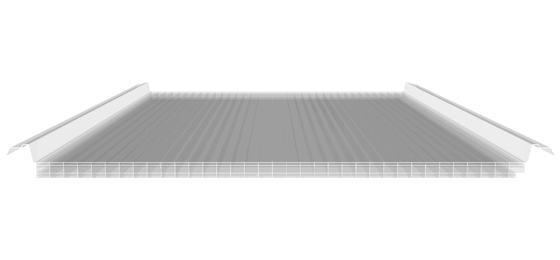

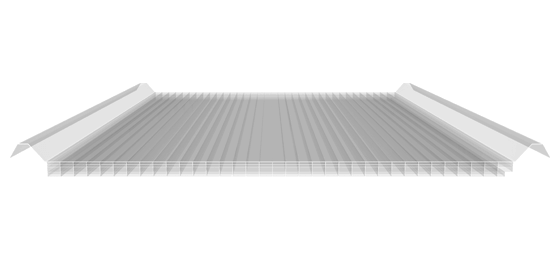

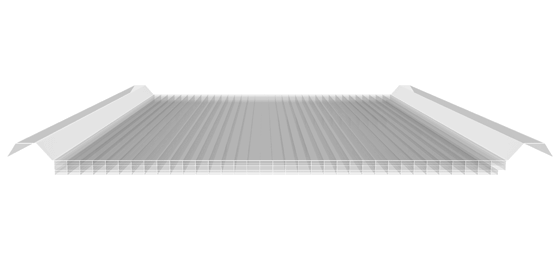

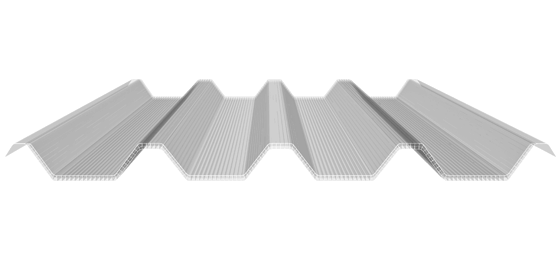

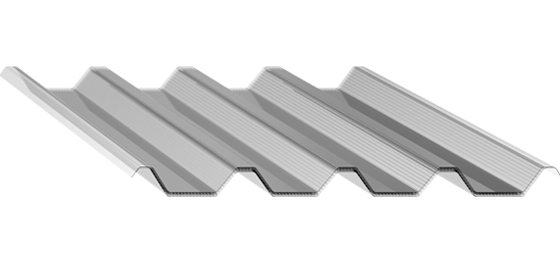

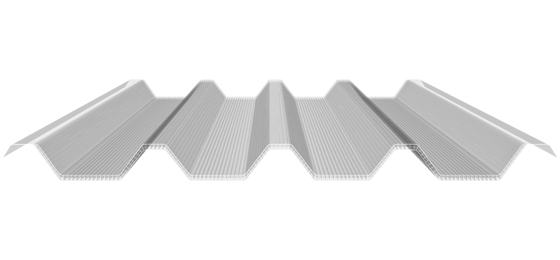

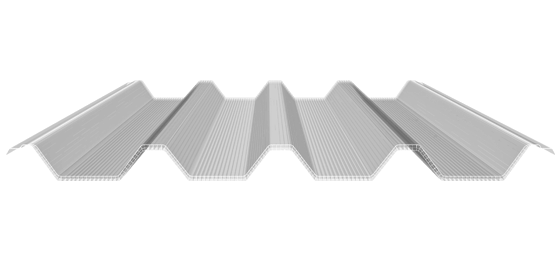

Assan Panel Polycarbonate sheet is produced in two types as Flat and Greka (trapezoidal) and is designed to meet all kinds of requirements.

Since they have the same cross-section in the connection with the existing capped and side-lapped Assan Panel sandwich panels, they show high-level compatibility in assembly, thus providing correct heat and water insulation. They have a heat insulation feature due to their closed cell structure. High impact resistance ensures that they are resistant to breakage. Thanks to their UV resistance, they protect the interior of the building from the harmful effects of the sun. They are produced as transparent or opal and meet different lighting needs in the building. They are preferred due to their lightness compared to glass applications used for light transmission.