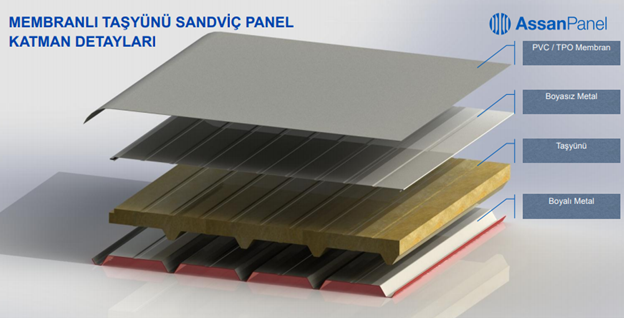

الألواح ذات الغشاء للسقف N5TM

وهي مادة لتغطية الأسقف التي يكون ميلها 1.5% على الأقل، وتتميز بمقاومة عالية للحريق وتوفر العزل الحراري وعزل المياه المطلوبين. تتميز بإمكانية تركيب أسرع وأسهل واقتصادية أكثر، مقارنة بالتطبيقات البديلة لها. يلتصق الغشاء الموجود في الألواح الغشائية للسقف N5TM، التصاقًا مباشرًا في المعدن وليس في مادة الحشو. تمتلك مقاومة عالية للضغط، والغشاء يوفر ميزة بصرية حيث يمنع التغيرات والآثار والطيات التي قد تحدث على السطح، ويزيد قدرة تحمل الألواح.يمكن اختيار الألواح ذات غشاء البولي فينيل كلوريد أو ذات غشاء البولي أوليفين البلاستيك الحراري.

- تتمتع بأداء عالٍ في العزل الصوتي، وبأداء امتصاص الصوت من الدرجة أ.

- بالإضافة إلى ذلك، يمكن استخدامها بأمان في المباني ذات مخاطر الحريق العالية وفي المباني التي يكون الحد الأقصى لمقاومة الحريق مرغوبًا، لأن حشوها الداخلي هو مادة الصوف الصخري

- It is a roofing material manufactured from rock wool filled sandwich panel with membrane bonded to the upper metal.

- Since the structure of the lower metal consists of 5 ribs, it has a high carrying capacity.

- By the combination of the lower and upper metals, the integrity of the core material is preserved and a multi-layered composite structure is formed.

- Thanks to this composite structure; It has a high carrying capacity due to the compression, tensile and shear strength it shows.

- In addition to the lateral overlap of the lower metal after the joint, the joint of the upper metal with the tongue-and-groove ensures that the coating works as a whole, providing high-level static strength performance.

- During the assembly, the sandwich panel is fixed to the construction via the upper metal. Since complete joint is provided at every point, there is no risk of separation of the Membrane Upper Metal layer. Deformation of the core filling material is prevented.

- Since it does not require pre-drilling; It provides an advantage by speeding up the assembly even more.

- The fastener connection element with mechanical fixation grasps the upper metal and remains under the welded membrane ear. Since the screw remains under the membrane; it is not exposed to external environmental conditions that will create a corrosive effect. The absence of corrosion extends the life of the material.

- -nlike on-site application systems, architectural visuality is achieved since no screw is visible on the interior ceiling surface.

- Making mechanical fixation starting from the membrane increases the resistance of the membrane against separation, especially due to the increasing wind load in very high structures. Both membrane lamination and mechanical fixation increase the strength by ensuring that the material works holistically along the entire surface.

- The resistance of the laminated surface against deformations offers the opportunity to walk on it during the use of the structure after assembly and during periodic maintenance.

- It is resistant to tears that may occur as a result of cutting and piercing tools falling on it during assembly or in construction site conditions.

- Even if the membrane ruptures, the metal layer underneath prevents the insulation filling material from being directly exposed to external effects. This aspect provides advantages in the use of the structure after assembly and in periodic maintenance. This makes the material longer lasting.

- It can be used on roofs with a minimum slope of 1.5%.

- In cases where the panel length is not sufficient on the same scissor arm, the panels are applied by overlapping them lengthwise.

- Since the composite system is produced with continuous line technology, it is more reliable than on-site application systems in terms of quality performance.

- It offers easier and faster assembly compared to on-site application systems.

Architectural Solutions with Membrane Rockwool Sandwich Panel

Unlike on-site application systems, architectural visuality is achieved since no exposed screws are visible on the interior ceiling surface.

Performing mechanical fixation starting from the membrane increases the resistance of the membrane against separation, especially in very high structures due to increased wind load. Both membrane lamination and mechanical fixation increase the strength by ensuring that the material works holistically across the entire surface.The resistance of the laminated surface against deformations offers the opportunity to walk on it during the use of the structure after assembly and during periodic maintenance.

It is resistant to tears that may occur as a result of falling on cutting and piercing tools during assembly or in construction site conditions.

لم يتم الحصول على نتيجة

معلومات المنتج

موقع الإنتاج

باليكسير

صافي عرض التغطية

1000 ملم

الحد الأدنى للطول

3 أمتار

الحد الأقصى للطول

يعتمد على ظروف النقل

كثافة الصوف الصخري

100 (±10 م3/كغم)

سمك الصوف الصخري

50-60-70-80-100-120-130-150 mm

معامل العزل الحراري

0,043 W/ mK

امتصاص الماء (EN ISO 354)

2% وفقا للحجم

مقاومة درجات الحرارة

600 درجة مئوية

عزل الصوت - مؤشر خفض الصوت [ديسيبل]

30

مقاومة انتشار البخار (EN 12086)

1